Liquid sample dispersion is the reference method against which dry dispersion methods are validated due to its gentle nature and wide applicability. The application of agitation and ultrasound can also be used to aid dispersion of agglomerates. Although slower than dry powder dispersion methods, liquid sample dispersion is applicable to a wider range of sample types due to the variety of liquid dispersants, surfactants and stabilizers that are available and which ensure that reproducible dispersion is achieved. Liquid sample dispersion is a gentle and effective sample preparation method for particle size analysis, especially when handling materials that are very fine (less than 20 μm in size) or are sticky/cohesive. To bring this process under control, users must understand how the measured particle size is dependent on the dispersion energy applied to the sample.

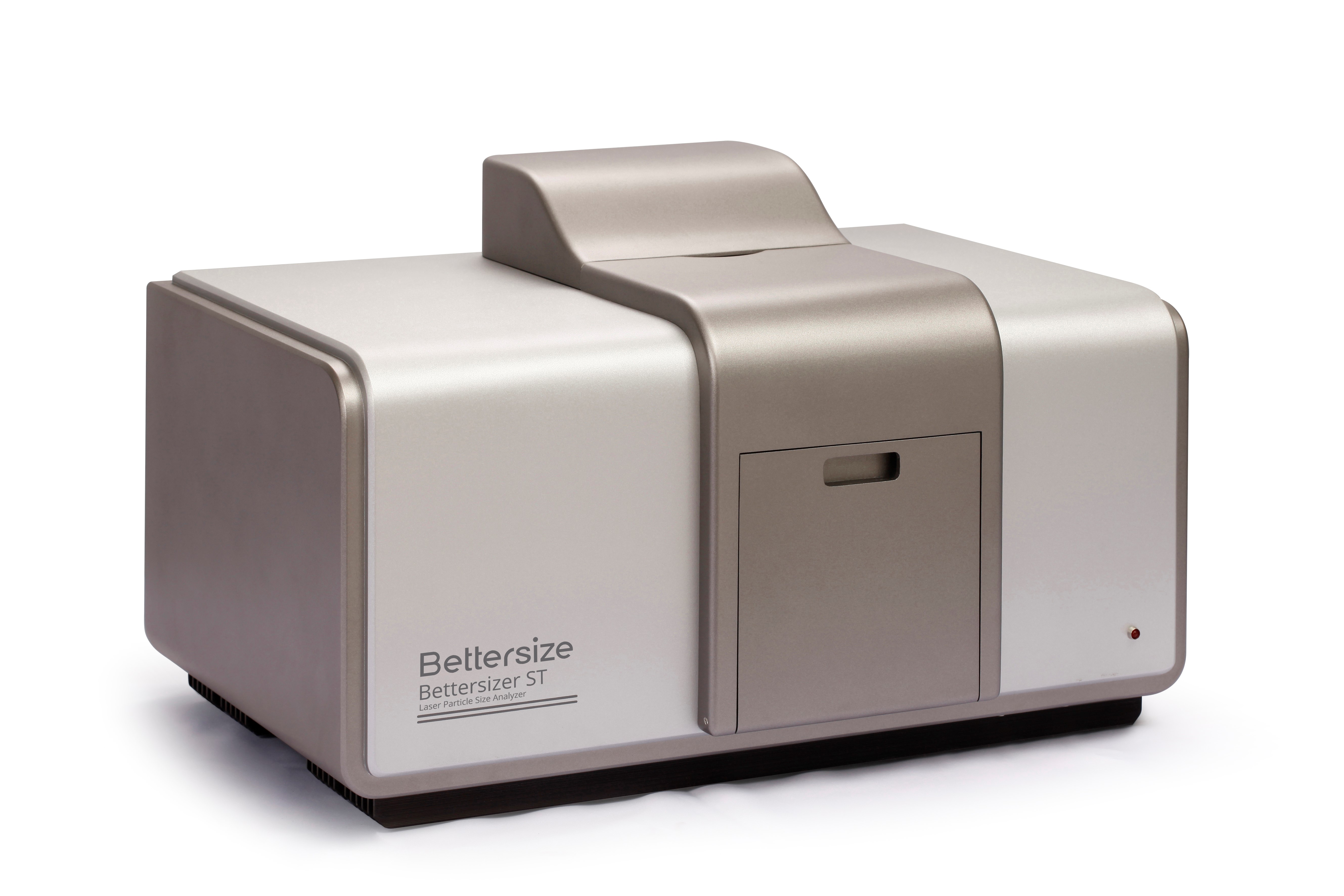

This means that any agglomerates within the sample must be reliably and reproducibly dispersed ahead of measurement. However, this level of efficiency and analytical productivity is not possible without sophisticated method development techniques in place.įor most applications, the desired output from a laser diffraction measurement is the primary particle size distribution for the sample. Today’s automated systems feature pushbutton operation and deliver exemplary measurement reproducibility and robustness. The appeal of laser diffraction derives from its flexibility and ease of use. This data is used to determine particle size distribution for the entire sample by comparing it to a mathematical model that predicts how particle scattering changes with particle size. Laser diffraction analyzers record the angular dependence of the scattered light intensity. Large particles scatter light at relatively narrow angles to the incident beam, while smaller particles scatter at much wider angles. Laser diffraction systems calculate the particle size distribution of a sample by first measuring the intensity of light scattered by the sample as it passes through a collimated laser beam. This article examines the role of imaging in particle size analysis and how it can help answer the question: “What does your particle size data mean?” Introducing laser diffraction

Imaging accessories that can be used in-line with laser diffraction analysis systems make it easier to exploit the synergies between these two important techniques.

Images of a sample support the development of a method that delivers complete dispersion without causing primary particle damage and provide valuable insight during troubleshooting. Imaging technology can be extremely helpful in assessing the efficacy of a dispersion process during laser diffraction measurement. Dispersion ensures that the particle size data generated is representative and relevant to the application. This is particularly true for systems containing the finer particles that are increasingly the focus of industrial interest. Highly automated and easy to use, modern laser diffraction systems efficiently meet the requirements for particle size data analysis in applications ranging from research and development through quality control.Īppropriate dispersion of a sample ahead of measurement is essential, and remains a potential source of error. Laser diffraction is a mature technology with extensive capabilities.

0 kommentar(er)

0 kommentar(er)